Alternate dimension: Architecture program expands learning opportunities with 3D printers

Emma Fierberg | Asst. Photo Editor

A 3-D model made by one of the new printers in the Architecture building.

The architecture program at Syracuse University is adding a new dimension to its printing and models — literally.

The school recently added a 3-D printer to the two it already had on campus. The new model is both cheaper and more user-friendly than previous ones, making it much more accessible to students and faculty. 3-D printing is used to create prototypes for projects, making the modeling process a lot easier.

It may not seem like it, but 3-D printers are similar to regular inkjet ones, as far as taking an image and copying it. The biggest difference is that 3-D printers take the image constructed through a digital modeling program and create a physical, three-dimensional object that you can hold in your hands.

Most importantly, 3-D printers allow students to create and experiment with new content, said Anrai Pearson, a third-year architecture student who has worked mostly with precision and abstract designs with the new technology.

“The 3-D printers allow us to expand our formal repertoire so we can produce more interesting forms,” he said. “(Without the printers,) it’s really difficult to model curvy forms and more complex forms.”

The machine does so by a layering process where it copies the computer model, or CAD file, one level at a time until it has reached the very top.

The program primarily used by SU architecture students is Rhino. Students create their computer models and send them to Chuck Savage and Andy Molloy, SU’s technical “gurus” for the printers, who operate the devices.

Pearson explained that in order for the printer to operate, the machine has to be able to recognize the file as an object. Pearson said the forms are generated in Rhino, and then turned into a “mesh,” which estimates the intended design shape. That “mesh” must then surround a solid, airtight form before it can be printed.

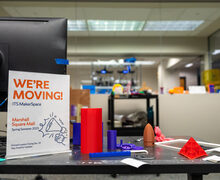

Emma Fierberg | Asst. Photo Editor

The MakerBot is one of the three 3-D printers in the architecture program. It takes anywhere from 1 to 35 hours to complete a print.

Tope Olujobi, a third-year architecture student, said the 3-D printer projects that she has been involved with are also focused on precision, which has been the main theme of these machines. The only disadvantage to the printers, she said, is the cost.

“Most of the time, most of the models are expensive to do,” Olujobi said.

Of the other two older models, prices can range from up to $4 per cubic inch to $7.25 per ounce of plastic used. The newest 3-D printer in the architecture program, however, costs about $2 every time a model two to three inches is printed.

Olujobi said she hopes that the process won’t require a large budget for projects in the future.

Molloy, one of the technical experts with 3-D printers, said the trend is that the machines are getting cheaper and cheaper. He sees the printers becoming “household” technology.

“I wouldn’t be surprised if students end up having them in their dorms, just like inkjet printers,” he said. “If they can make a 3-D model of it on the computer, they can have it as a physical object, which is pretty remarkable.”

The filament is made out of a plastic that is actually food-safe and could be used to hold meals, Molloy said. Other materials used in the past for older 3-D printers were unbearable as far as smell, he said, adding that people would not want to be in the same room during a printing job.

Both Pearson and Olujobi said making models by hand is very time consuming and difficult, adding that it is much easier to have the machine automatically create the model.

But there is still a time investment with the printers.

The student who is printing usually stays with their project as the printer prints. Any print job can take from 1-35 hours to complete, which all depends on the size of the model. With the newest model, the largest possible printed model size is 11 inches by 6 inches by 6 inches.

Not only are 3-D printers available for architecture students, but also those in the School of Information Studies, along with other design fields. There have been projects such as those in fashion that have used the technology to their advantage.

Anthony Rotolo, an iSchool professor who specializes in 3-D printing, said the technology’s effect on industries across campus has been amazing. Rotolo has also co-authored an informational book on the new technology.

“3-D printing is like any printing in the sense that you have an idea that you want to produce,” Rotolo said. “The thing that is unique is that it is offering more physical, real-world possibilities. It’s used in the architectural field, project design and ITS fields. It gives you a physical prototype to work with.”

Published on January 22, 2014 at 10:46 pm

Contact Claudia: ctceva@syr.edu